The Role of Welded Wire Mesh Panels in Industrial Enclosures

Welded wire mesh panel serve a vital function in various industries, providing protection, safety, and containment for equipment, machinery, and processes. When it comes to constructing durable and secure enclosures, welded wire mesh panels play a crucial role. Let's explore the significance of welded wire mesh panels in industrial enclosures and how they contribute to the smooth operation of industrial facilities.

Structural Integrity: Welded wire mesh panels offer excellent structural integrity, making them an ideal choice for constructing robust industrial enclosures. The panels are fabricated by welding intersecting wires, creating a rigid and stable framework. This structural strength allows for the construction of large-scale enclosures that can withstand mechanical stresses, environmental conditions, and potential impacts. Welded wire mesh panels ensure the longevity and durability of industrial enclosures, providing a reliable and safe environment for equipment and processes.

Security and Safety: Industrial enclosures often house valuable assets, sensitive equipment, and critical processes that require protection and security. Welded wire mesh panels provide a high level of security by creating a barrier that is difficult to breach. The welded mesh design prevents unauthorized access, deters intruders, and enhances safety within the enclosure. Additionally, the clear visibility offered by the mesh panels allows for easy monitoring of activities inside the enclosure, ensuring prompt response to any potential security or safety issues.

Ventilation and Airflow: Many industrial processes require proper ventilation and airflow to maintain optimal conditions. Welded wire mesh panels facilitate the circulation of air within the enclosure, allowing for efficient ventilation and heat dissipation. The open mesh design of the panels ensures that airflow is not hindered, preventing the accumulation of heat or the build-up of harmful gases. This ventilation capability is crucial in maintaining a safe and controlled environment for equipment and personnel.

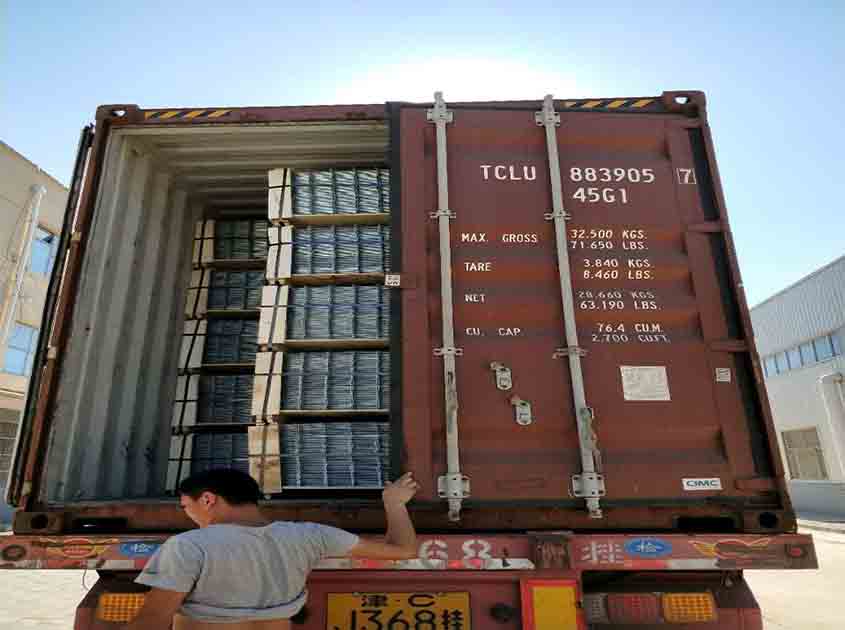

Flexibility and Adaptability: Welded wire mesh panels offer flexibility and adaptability in industrial enclosure design. The panels can be easily cut, shaped, and welded to fit the specific requirements of the enclosure. This flexibility allows for customization and modification, accommodating different enclosure sizes, shapes, and layouts. Welded wire mesh panels can be integrated with other enclosure components, such as doors, frames, and roof systems, to create a seamless and functional enclosure solution.

Visibility and Access: Clear visibility is essential in industrial enclosures, as it enables efficient monitoring, maintenance, and troubleshooting. Welded wire mesh panels provide transparency, allowing for easy visual inspection of equipment, processes, and infrastructure. The visibility offered by the mesh panels facilitates routine maintenance, inspections, and repairs, minimizing downtime and ensuring the smooth operation of industrial facilities. Moreover, the panels can be designed with hinged or sliding doors, providing convenient access points for personnel and equipment.

-

Best Welded Wire Mesh for South American Markets Feb 03, 2026

Best Welded Wire Mesh for South American Markets Feb 03, 2026 Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China